Forestier, aghast, reveals to Mathilde that the necklace she lost was just a fake. Forestier the sad story of the necklace and her ten years of poverty, and she does.

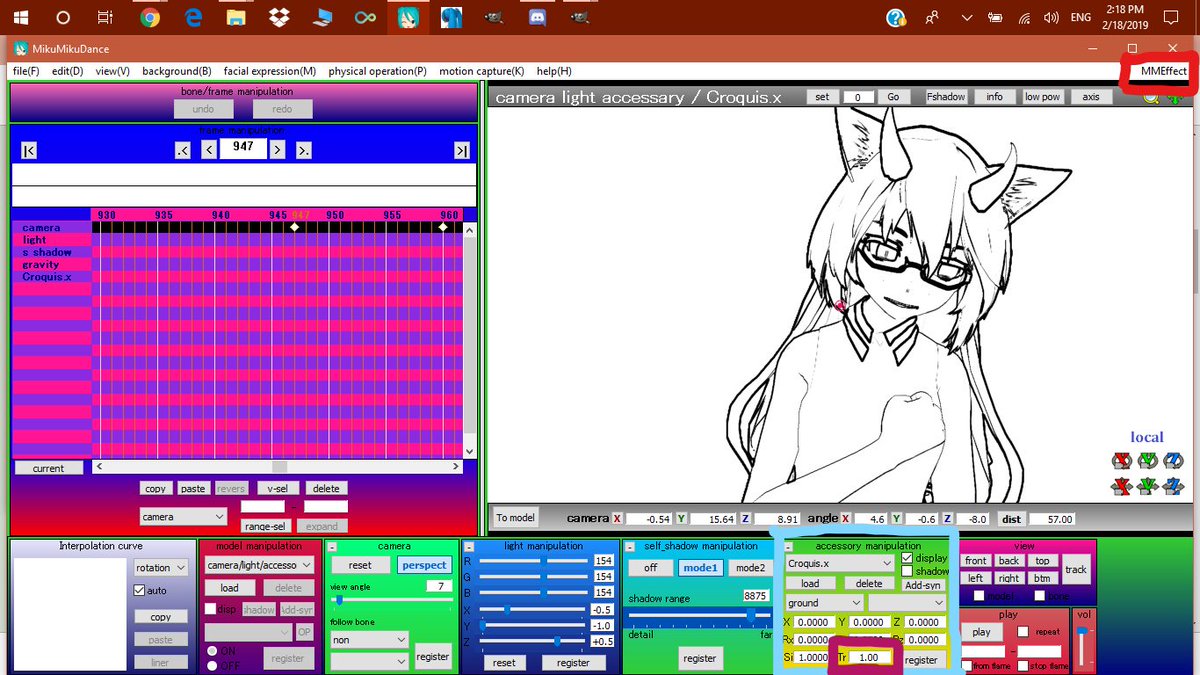

MME EFFECT DOWNLOAD

as well as a peak respiratory depressant effect occurring later and lasting longer than its peak analgesic effect. MME Effects Tutorials MotionBlur3 Effect adds visual reality to your MMD videos and stills Why would I use Soboro’s MotionBlur3 effect Where can I download the MotionBlur3 effect How can I catch the blur in a still image MotionBlur3 Effect adds visual. Now that all the debts are paid off, Mathilde decides she wants to finally tell Mme. The results show that the quality, geometry, and hardness of solidified melt pool are significantly affected by laser power, scanning speed, and laser energy density. The MME/day metric is often used as a gauge of the overdose potential of the amount of opioid that is being given at a particular time. Findings of increased fracture risk for current opioid use, versus nonuse, were mixed in two studies ( 68, 69 ). In addition, the observed unfavorable effect such as inconsistency in melt pool width formation is discussed. Relative to 119 MME/day, the adjusted odds ratio (OR) was 1. MME/day, 1. MME/day, 2.99 MME/day, and 2.88 for 200 MME/day. This experimental study investigated the influence of laser power, scan speed, and laser energy density on the melt pool formation, surface morphology, geometry (width and height), and hardness of solidified beads. Multiple combinations of laser power and scan speed were used for single bead fabrication, while the laser beam diameter and powder layer thickness were kept constant. This product was identified by FDA during an examination. In this study, single beads of commercially pure titanium (CP-Ti) were melted on a substrate of the same material using an in-house built SLM machine. The Food and Drug Administration (FDA) is advising consumers not to purchase or use MME MAXMAN, a product promoted for sexual enhancement. The effect of gas enrichment and mixing on oil recovery is examined for several one-dimensional four-component gas/oil systems where dispersion-free analytical solutions are known. In SLM, the process parameters decide the quality of the fabricated component. The main focus of this paper is to demonstrate that in the presence of dispersive mixing oil recovery can increase significantly as gas is enriched above the MME. Selective laser melting (SLM) is an additive manufacturing technique that creates complex parts by selectively melting metal powder layer-by-layer using a laser.

0 kommentar(er)

0 kommentar(er)